SYSTEMS AND V&V

As part of our engineering activities, our teams deploy our in-house systems engineering process dedicated to turnkey Design and Production projects. We implement a functional analysis in order to reflect the client’s needs into adapted product architecture. We decompose the normative, industrial and environmental constraints towards our business lines (electronics, mechanics, electricity, prototyping, testing) for the development phase and the integration, validation and verification phase. The coverage of needs is held by a performing traceability and adaptation to requirements together with the drafting of justification and testing files (reliability, AMDEC, simulation, calculation note, physical tests …).

OUR SKILLS

- Needs functional analysis

- Requirements management

- Product architecture

- Reliability analysis

- Check by test operation or analysis

ELECTRICITY & CONTROL SYSTEMS

Now, this experience enables Ametra Engineering, working with its sister company Ametra Integration, to offer works packages in electronic engineering.

OUR SKILLS

- Synoptics

- Functional and Technical Design

- Detailed and interconnection diagrams

- Cable diagram and harness

- Locations: Electrical cabinets, switchboards, etc

- Environmental constraints: hazardous machines, EMC, hazardous areas, etc

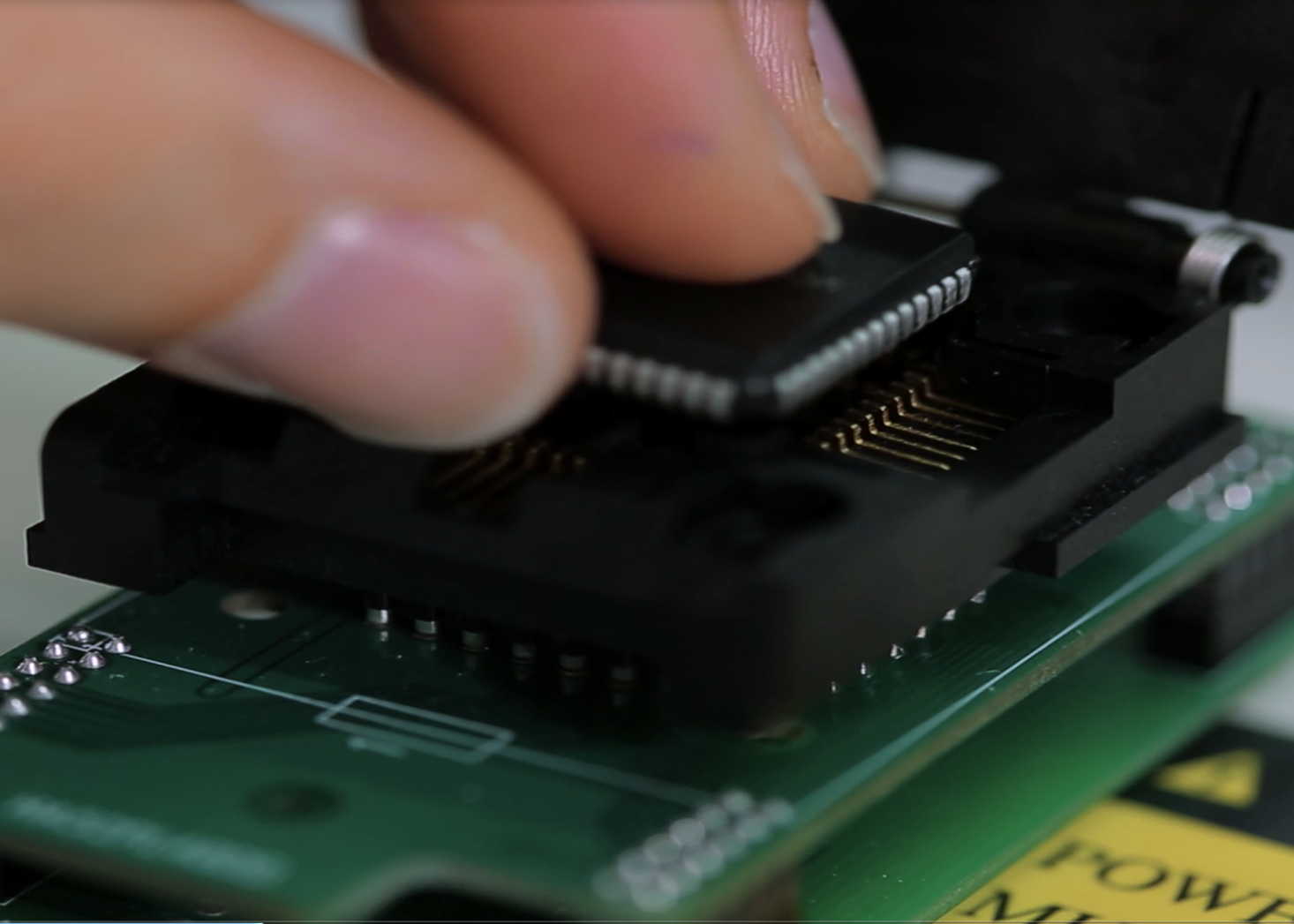

Electronics & software

- Electronic architecture

- Analogue and Digital

- Distribution and Conversion

- Schematic

- Routing

- Prototyping and test

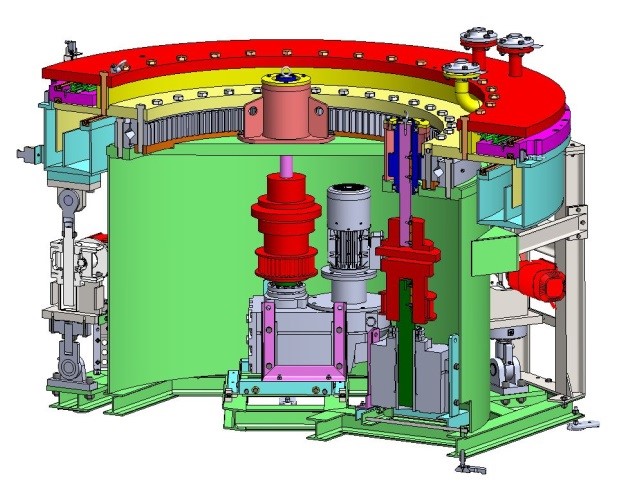

MECHANICS

Our designers, design engineers and engineers support our clients in their product study and systems projects. Based on our strong multi-sector experience, we use our skills to meet the requirements of the project. Our know-how covering the entire design chain and our control of project management enable us to provide a global offer, from drafting the specifications to industrial management.

OUR SKILLS

- CAD

- Work procedures

- FMECA

- Analysis of value

- Digital simulation

- Analysis and functional dimensioning

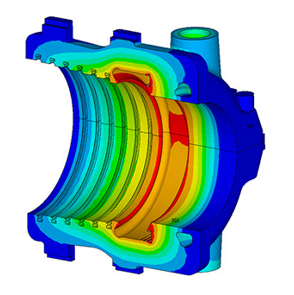

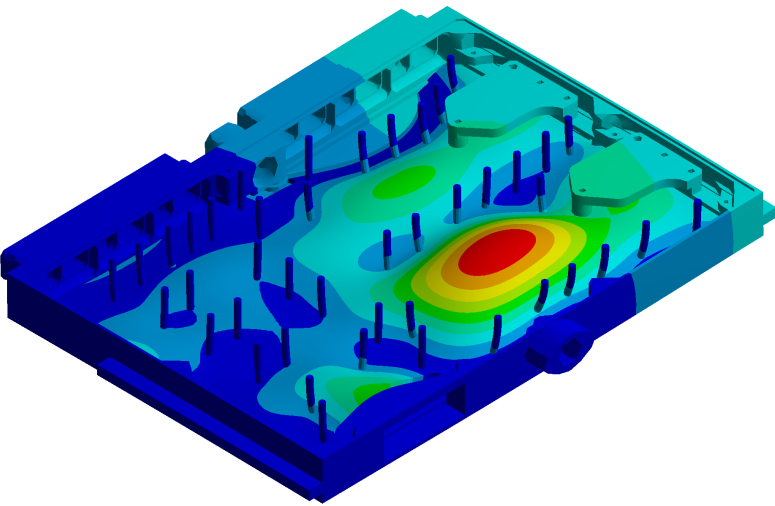

CALCULATION & SIMULATION

Ametra Simulation's aims: modelling physical phenomena to better control them.

OUR SKILLS

- Study of how complex systems and objects in design stage function and their properties - without building a prototype.

- Assessment of the benefits and risks of a technology, comparing different technical solutions.

- Improving the quality of finished products and supporting their technical developments.

- Optimisation of industrial processes.

- Reduction of development and manufacturing costs.

PLASTIC & COMPOSITE MATERIALS

OUR SKILLS

- Design, Files, Analysis of the value, Meeting specifications, etc...

- Materials, Aesthetics, Cost, Mass, Functional, Industrial, etc...

- Choice of materials & Technology

- Model & Prototype

- Industrial support

DESIGN & ERGONOMICS

The expected results of creativity: imagination, innovation. Real creativity does not mean adapting an existing product, but rather inventing a product that expresses a strong concept, meets needs that are not satisfied, explicit or implicit, as well as provide solutions to solve malfunctions.

OUR SKILLS

- Analysis

- Pre-project

- Design

- Expertise

- Definition

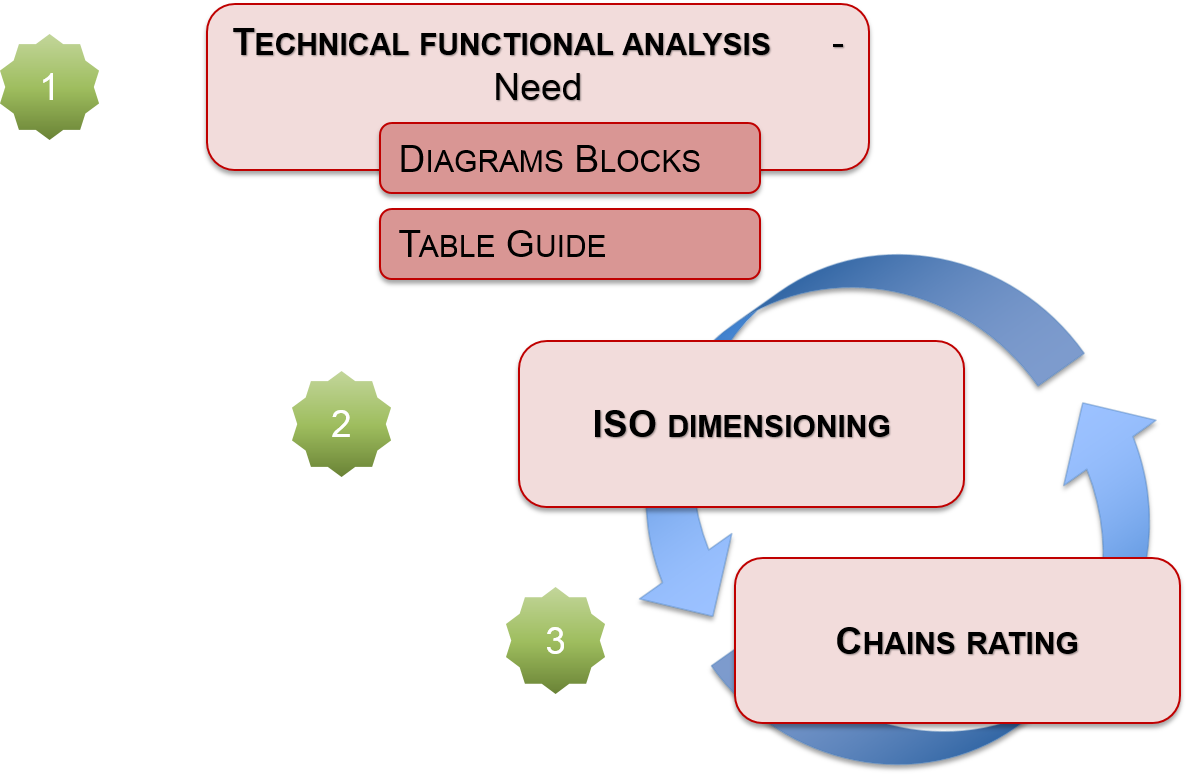

ANALYSIS & TOLERANCING

OUR SOLUTIONS

- Standard training

- Tailored training

- Support days

- Hotline

- Expertise

OUR EXPERTISE

- Functional analysis

- ISO dimensioning

- Tolerancing

OUR TOOLS

- Tolerance Manager

- CeTol

PROJECT MANAGEMENT

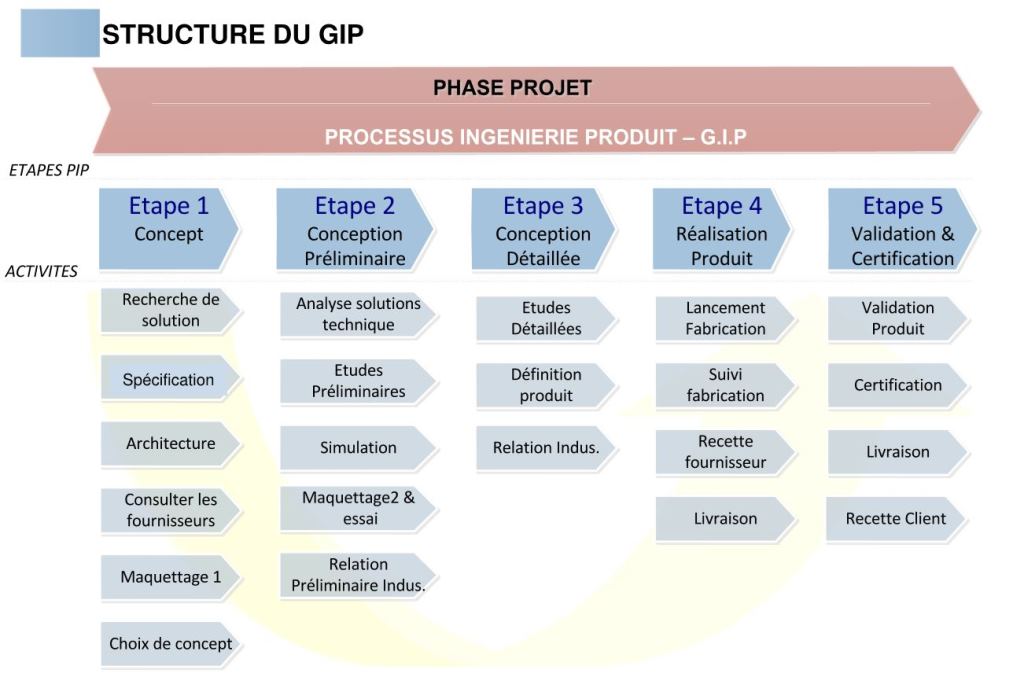

Our process is also reinforced by a Product Engineering Guide "G.I.P", which enables Ametra Engineering's teams to work in simultaneous engineering mode, involving all sectors from the start stage of the project.